drop and hardness test of grease|lubricant dropping point : factories This test is quite simple from a laboratory experiment standpoint, but the recorded dropping point provides valuable insight into the temperature properties of grease and the proper applications it can be applied for. 27/06/2023 10h22. A influenciadora Kine-Chan, 21, lançou uma boneca sexual com suas medidas e já atraiu atenção de fãs. Um deles comprou a peça e resolveu assumir .

{plog:ftitle_list}

Resultado da 4 horas atrás · Última atualização em 1 de março de 2024 às, 08h33. A CBF divulgou nesta quinta-feira, 29, a tabela do Brasileirão Série A de 2024. A competição terá início entre os dias 13 e 14 de abril, com término em 5 de dezembro. A novidade anunciada pela CBF é que esta será a primeira .

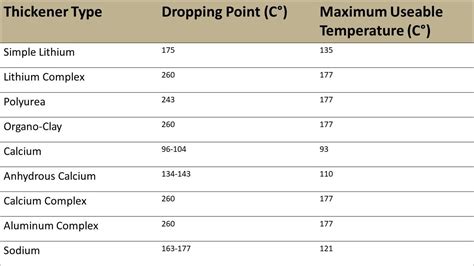

Dropping point of a grease is the temperature at which a drop of grease material falls from the orifice of the test thimble size cup under a prescribed ramped temperature program. ASTM D 2265 is a procedure that uses an aluminum . This test is quite simple from a laboratory experiment standpoint, but the recorded dropping point provides valuable insight into the temperature properties of grease and the proper applications it can be applied for.

lubricant dropping point chart

ASTM 1478 is a grease low temperature torque test that in - vestigates the ability of a grease to lubricate a slow rotating ball bearing. The test records starting and running torques at .

The dropping point test determines the cohesiveness of the oil and thickener of a grease. Dropping point tests are used for quality control to verify that the soap structure has been formed correctly and will withstand high temperatures.This test method is useful to assist in identifying the grease as to type and for establishing and maintaining bench marks for quality control. The results are considered to have only limited . In this article, we’ll take a look at the standardized testing done to worked, un-worked, and prolonged worked grease to determine a grease’s properties. If requested, your grease supplier should be able to provide grease .

A recently developed grease test is the RULER test (L) ASTM D7527 Remaining Antioxidant by Linear Sweep Voltammetry, which measures the remaining phenolic and aminic antioxidants .Dropping point is the temperature at which a grease becomes fluid enough to drip. The dropping point indicates the upper temperature limit at which a grease retains its structure, not the .first drop of material falls from the test cup; that temperature being the average of the thermometer readings of the sample and bath. 3.2.1.1 Discussion—In the normal and proper operation of this test method the temperature of the interior of the grease test cup and the temperature of the oil bath are monitored simultaneously as the bath is .Dropping point test of grease The dropping point of lubricants is an important test method for lubricating greases to assess the quality of these materials. The dropping Point test determines the cohesiveness of the oil thickener of a grease.

(where the base oil leaves the grease thickener) — gives good insight into high temperature performance. ASTM D2265 is a standard method for measuring the dropping point of grease. In this test, grease samples are gradually heated until the thickener can no longer hold the base oil and drips start to occur. The market offers many ul-1. A grease is formed by thickening oil with gelling agents to make it stiff so that it stays in place while gradually releasing oil into loaded components. 2. The dropping point of a grease is the temperature at which it passes from semisolid to liquid state, as measured by supporting a grease sample in a test cup in an oven and recording the temperature when a drop falls from the cup. .

method yield results useful for identifying grease as to a type and for establishing and maintaining benchmarks of quality control [9]. In this test, a grease sample is heated and observed until a drop of material falls from the cup to the bottom of the test tube. The Koehler Instrument Company Inc, apparatus for the DroppingIf the grease cannot withstand the water it may become soft or watery and the quality will drop. The amount of water in a grease sample is calculated exactly using the Karl-Fischer method in ppm (mg/kg), the same method as for oil. To do this, water must be „driven out“ of the sample. . The test shows the percentage of base oil that the . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .View 445532792-Drop-and-Hardness-Tests-Of-Greases-pptx.pdf from MENGR 320 at Central Luzon State University. Drop and Hardness Tests Of Greases By: MarbenJohn L. Guirigay Dropping Point of . Lesson 3 - Experiment 3 Flash & Fire Points of Liquid Fuels and Grease Drop Test.ppt. Far Eastern University. ENGINEERIN 111. Mechanical Engineering .

The consistency test provided in the SKF grease test kit is intended for the in-service sampling of grease and needs only a very small sample. This consistency test is an example of a constant-volume squeeze flow . It is done by first applying a cylindrical-shaped sample of grease to a glass plate using a jig. Then, another glass plate is . In this test, a grease sample is heated and observed until a drop of material falls from the cup to the bottom of the test tube. The Koehler Instrument Company Inc, apparatus for the Dropping Point Test is shown below in Figure 1 [10]. . [11] Kumar, K. B. V. S. S., Reddy, C. J., & Ramesh, K. V. (2020). (PDF) study on Drop Point of grease .

The 4-ball wear test is used as a method of measuring the grease's ability to prevent wear under demanding conditions. The grease's wear resistance is examined in sliding contacts steel on steel. The test is set up the same as the 4-ball weld test, but with a limited load and more sensitive equipment.

The drop point is the temperature at which the lubricating grease liquefies as a result of the disintegration of the soap structure (thickening agent), i.e. when the liquefied grease drop falls through the opening in a nipple onto the bottom of the test tube. Statement: The drop point is mainly an indicator of quality control for manufacturers. DROP AND HARDNESS TEST. Flashcards; Learn; Test; Match; Q-Chat; Get a hint. Dropping point-is an indicator of heat resistance of grease, as grease temperature rises. 1 / 24. 1 / 24. Flashcards; Learn; . the ability of a grease to withstand the effects of water with no change in its ability to lubricate.Table 2 gives some examples of the useful and yet at times misleading information that drop-point determination can give as regards the relatively higher temperature perfor mances of greases assessed in a high-temperature bearing test. Grease A with a drop point of 185°C has a negligible life in a bearing rig test run at 175°C, only lOoC .

In the test, a cup is filled with a given quantity of grease (and is weighed before the test) and a 100 gram weight is placed on top of the grease. The complete unit is placed into an oven at 40 °C (105 °F) for one week. At the end of the week, .Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y

lubricant dropping point

For the present study four types of grease samples were obtained from different outlets. Table 1 presents the details of these samples and their drop points. Table 1 DROP POINTS OF DIFFERENT GREASES . S.No Type of Grease Drop Point . 1 Reliance grease NLGI-3 174. o. C 2 HPCL grease NLGI -3 173. o. C 3 Multipurpose grease 99. o. C 4 Pensol wheel .6.3.1 Grease Worker Drive, Manual, in accordance with A1.5, which allows for working the grease at a rate of 60 6 10 double strokes per minute. 6.3.2 Grease Worker Drive, Motorized, in accordance with A1.6, which allows for working the grease at a rate of 60 6 10 double strokes per minute. This apparatus is essential for the

If a grease can emulsify water, there is a risk of corrosion and hydrogen embrittlement. A simple test for water resistance involves placing a thin layer of grease on a strip of glass. If the layer of grease turns a cloudy, milky color or dissolves from the glass strip entirely, the grease will absorb moisture when stored in water.The cone is allowed to drop into the grease; . The hardness of the composite increased with the increasing content of WS 2 and reached the maximum value of 94.7 H V at 30 vol%, . An important characterization test of grease is evaluation of its use in a wear situation. Wear tests usually utilize two surfaces rubbing against one another with .

Drop point is defined as the temperature at which it passes from the semi-solid to the liquid state. At this condition, a drop of grease sample falls from the orifice of the test apparatus. This methodology confirms to the ASTM D 2265. This temperature determines the upper temperature limit of the applicability of the grease. Four Ball Extreme Pressure (EP) Test: evaluates the extreme pressure properties of the grease. (ASTM D2496) Timken EP Wear Test: evaluates the load carrying ability of the grease. (ASTM D2509) Bleed Rate. Measures the resistance to oil separation from the thickener. This test is done as some greases tend to separate while in storage. (ASTM D1742)

The cone is allowed to drop into the grease; the amount of penetration is measured by the penetrometer in tenths of a millimeter. The greater the penetration, the thinner the grease consistency. . DSC works by placing a sample of used grease into a test cell. The cell is heated and pressurized with oxygen. When the grease starts to oxidize .A number of factors influence hardness tests results. As a general rule, the lower the load you use in the hardness test, the more factors that need to be controlled to ensure an accurate conclusion of the hardness test. Here are a few of the most important factors to consider to ensure an accurate conclusion from a hardness test.3. Flash and Fire Points of Liquid Fuels and Grease Drop Test - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document outlines an experiment to determine the flash point and fire point of liquid fuels and greases using an open cup method. The flash point is the lowest temperature at which a fuel .The intent is to test the grease samples with a similar level of pre-conditioning for a more consistent result. The common pre-conditioning of a worked cone penetration sample test is to be sheared for 60 strokes. However, this pre-conditioning practice is only intended for new greases. In-service grease receives no pre-conditioning prior to .

grease dropping point chart

2.4 multiair engine compression test

The relative hardness of a grease, as specified by the National Lubricating Grease Institute (NLGI). Penetrometers measure consistency of greases! A cone penetrates the grease for five seconds. Value = depth of penetration (mm) x 10.! Grease “worked” for 60 or more double strokes simulates consistency of grease in an operating environment. !

2.7 t compression test

20 pc diesel engine compression tester

webSeja um empreendedor solar de sucesso com a 77! Nossa Plataforma é o maior ecossistema de energia solar do Brasil e a única 100% gratuita! 🚀. Resposta rápida e as .

drop and hardness test of grease|lubricant dropping point